ROSEN Group onthult nieuwe service voor het opsporen van corrosie in opslagtanks

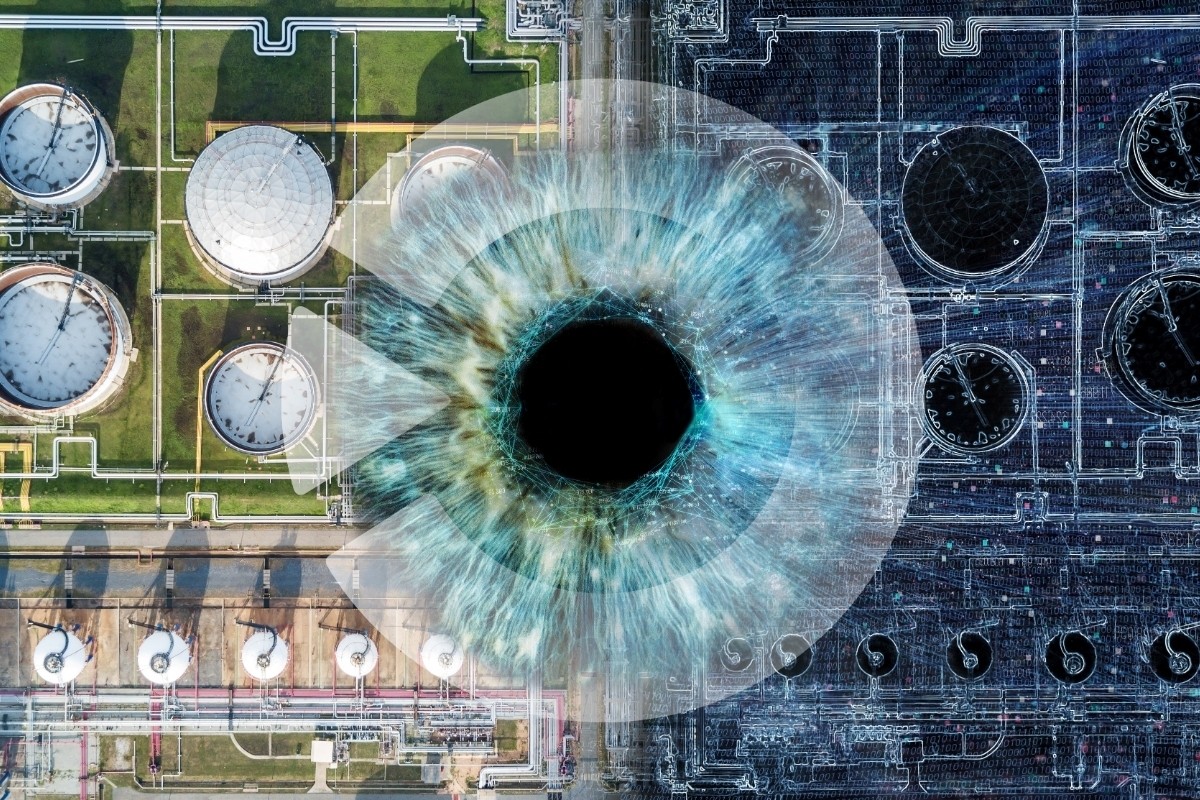

De opslag van koolwaterstof- en chemische vloeistoffen in bovengrondse opslagtanks is een belangrijk onderdeel in de energie waardeketen. Hierbij is de conditie van de bodem van de opslagbodem belangrijk, deze zorgt voor de betrouwbaarheid van de opslagtank. Corrosie is een van de meest voorkomende bedreigingen voor de conditie van deze tankbodems. De inspectie- en kwaliteitsmedewerkers van ROSEN Group hebben zich verdiept in de complexiteit achter deze bedreiging en de TBIT Ultra-service is hiervan het gevolg.

Datum van publicatie: 17 augustus 2020

Lees tijd +/- 1,7 minuten

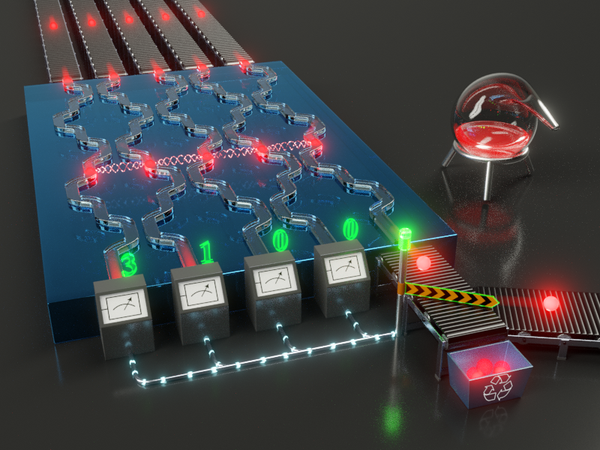

TBIT Ultra-service

TBIT stands for Tank Bottom Inspection Tool. ROSEN's service ensures that the time between two tank inspections (the inspection interval) is extended. It uses the latest technology and detects defects, determines the size and then reports these findings. This can be done from as little as 10 per cent wall loss, including defects caused by pitting corrosion. The time between inspections is greatly extended by using this technology and replacing defects when necessary, and storage tanks can be used for longer.

Optimising programmes for storage tank inspections

ROSEN’s new TBIT Ultra service makes it possible to detect and identify even the smallest defects due to metal loss caused by microbiological corrosion. The TBIT Ultra service allows operators to detect corrosion on the tank bottom at an early stage. These reliable detections ensure that the corrosion rate can be determined, and the storage tank’s maintenance management plan can then be drawn up or renewed. The time between inspections can be extended by up to 20 to 25 years by reliably detecting corrosion and quickly repairing it. The service can detect what actions are needed in both the short and long term, and the expenses can be optimised.

Webinars

ROSEN Group will give several webinars about the TBIT Ultra service. Participate in these webinars to find out more about this service and its advantages.

Up to date blijven?

“Ik vind security, van een hoger niveau, interessant”