WELKOM IN TWENTE

Twente biedt jou de kans om jezelf te ontwikkelen met uitdagende werkplekken in een innovatieve en inspirerende omgeving. Ontdek alle voordelen van het leven in Twente.

Ontdek waar Twente voor staat

Twente is dé plek waar vrijheid jou laat groeien. Hier krijgen grote ideeën de ruimte om te bloeien. Als professional krijg je hier alle kansen om jezelf te ontwikkelen. En als ondernemer kun je rekenen op een innovatief ecosysteem dat je uitdaagt om jouw dromen waar te maken. In Twente is het goed toeven: er is ruimte om te genieten.

In deze groene, technologische topregio werken we samen aan een betere wereld en de innovaties van de toekomst. Wij geven talenten de ruimte en hebben oog voor hoogwaardige technologische ontwikkelingen. Met baanbrekende technologieën zetten we Twente op de kaart. Zo hebben we lokaal, nationaal, regionaal én internationaal impact en maken wij het verschil voor morgen.

Maar in Twente draait het niet alleen om werk. Twentenaren zijn gelukkiger dan andere Nederlanders. Dat komt omdat hier ruimte is voor een sociaal leven en ontspanning. Even ontsnappen van de drukte? In Twente ben je in no-time in een park, bos of een van de gezellige dorpen of steden.

Liever op een andere manier je hoofd leegmaken? Sporten, spelen of genieten van een van de vele feesten en festivals. Hier is altijd wat te doen! Of je doet lekker helemaal niets. Jij hebt de vrijheid om te doen waar jij zin in hebt. Je viert het leven op jouw manier. Dat is Twente.

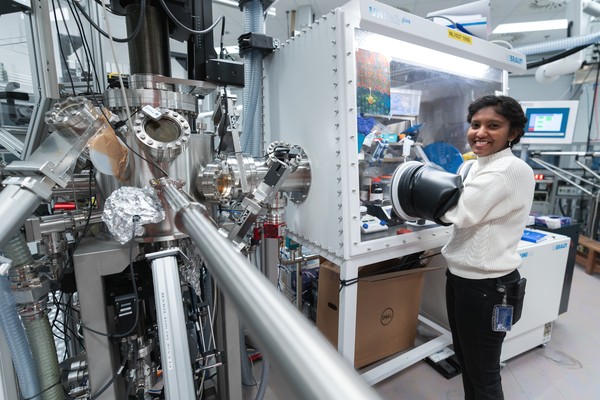

Werken en Leren

In Twente kun je als professional je droombaan vinden én jezelf ontwikkelen. Met uitdagende banen in hightech, zorg of de maakindustrie, biedt Twente volop groeikansen. Hier werk je aan je carrière en geniet je van een rijk sociaal leven. Dankzij de nauwe samenwerking tussen bedrijven en kennisinstellingen bruist Twente van mogelijkheden. Er is altijd een uitdaging die bij jou past.

Leer van experts, groei door opleidingen en inspireer je in een innovatieve omgeving. In Twente kun je jezelf zijn en je talenten optimaal benutten en inzetten voor thema's die jij belangrijk vindt. Lees de verhalen van mensen die je voor gingen, bekijk bedrijven die hier innoveren en ontdek jouw toekomst, in Twente natuurlijk.

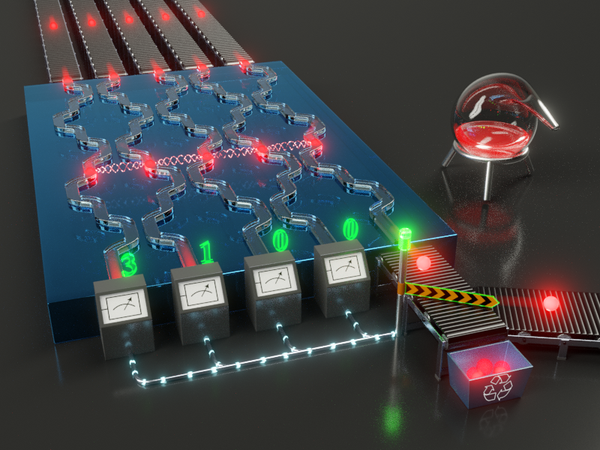

Next Tech Twente

Ontdek Twente, waar we werken aan de innovaties van morgen met geavanceerde technologieën. Denk daarbij aan levensreddende robotica, geavanceerde chips, de toekomst van energieopslag en industrie 4.0. Met focus op medische technologie, batterijtechnologie, chiptechnologie en nieuwe industrie is Twente een pionier in hightech. Wij noemen dat ook wel next tech, de technologie van de toekomst.

Hier wordt de eeuwenoude innovatieve ondernemersgeest gedreven door Twentse businessondersteuning, op onze innovatiecampussen maar ook ver daarbuiten. De open houding en samenwerkingsdrang van Twente maken het dé thuisbasis voor grensverleggende innovaties met wereldwijde impact, want in deze regio brengen technologie en vooruitgang samen.